The industrial borescope is an excellent indirect visual inspection device that provides operators with a non-intrusive way to conduct internal visual defect inspection and assessment. This makes the industrial borescope a truly "versatile inspection tool" in industrial testing. What can an industrial borescope do?

1.Defect Detection

The industrial borescope has the ability to uncover the secrets hidden inside the inspected objects. With its sophisticated design, the industrial borescope can navigate through tight spaces, convoluted pipelines, and deep within components. With bright illumination, responsive articulation, and high-definition imaging, the industrial borescope assists operators in thoroughly examining the internal structures of the inspected objects, identifying and documenting any existing defects.

2.Fault Prevention

Industrial borescope enables regular inspections during equipment operation to promptly identify potential failures or anomalies. By conducting borescope inspections, measures can be taken in a timely manner to repair or replace damaged components, thereby avoiding equipment failures that could lead to production interruptions or safety incidents, and improving production efficiency and safety.

3.Quality Control

During the production process, industrial borescope can be used to inspect the quality and integrity of products. By observing the internal structures, connections, and assemblies of products, it is possible to determine if they meet quality standards and regulatory requirements, preventing defective products from entering the market and ensuring product quality and customer satisfaction.

4.Exploration of Inaccessible Areas

Industrial borescope is capable of exploring hard-to-reach areas. Its flexible and slender probe allows for access to confined spaces, narrow passages, and remote locations that are difficult for operators to reach directly. This capability enables thorough inspections and investigations of inaccessible areas for maintenance, troubleshooting, or assessment purposes.

5.Maintenance and Upkeep

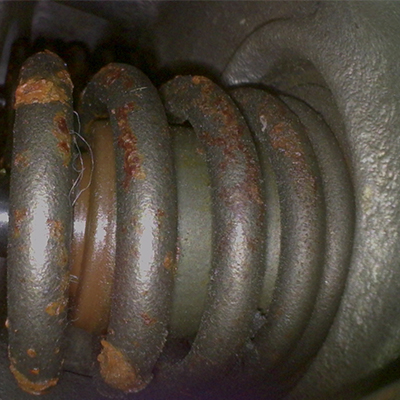

Industrial borescope can be used for regular equipment maintenance and upkeep. By inspecting the internal conditions of equipment such as wear, corrosion, and deposits, effective maintenance plans and upkeep strategies can be developed to prolong the equipment's lifespan and stability.

6.Safety Inspections and Risk Assessment

Industrial borescope can be utilized for safety inspections and risk assessments, particularly in high-risk industries or hazardous environments. Through borescope inspections, potential safety hazards, damaged components, or underlying risk factors can be promptly identified, and corresponding measures can be taken to ensure workplace safety.

7.Process Optimization and Design Improvements

By observing and documenting with industrial borescope, engineers and designers can understand the internal operating status and characteristics of equipment, identify issues or areas for improvement. This provides valuable information and reference for process optimization and design enhancements.

8.Monitoring Equipment Performance

Industrial borescope can be used to monitor the operating status and performance of equipment. By observing the degree of wear, lubrication, and working condition of internal components, it is possible to determine if the equipment is functioning properly, detect abnormal vibrations or noise, and take timely maintenance or adjustment measures to ensure reliability and stability of the equipment.

9.Preventing Blockages and Leaks

Blockages and leaks are common issues in equipment such as pipelines, conduits, and containers, which can lead to production interruptions, energy waste, or environmental pollution. Industrial borescope can be used to inspect the deposition, corrosion condition, and sealing performance inside pipelines, enabling early detection and repair of potential blockages and leaks, thus maintaining normal operation and production efficiency of the equipment.

10.Achieving Remote Inspection and Recording

With technological advancements, modern industrial borescopes have the capability for remote monitoring and recording. Operators can transmit the borescope's images and data to a remote terminal through network connectivity or wireless transmission, enabling remote observation and evaluation. This remote inspection and recording method facilitates the participation and decision-making of expert teams, improving inspection efficiency and accuracy.

11.Enhancing Work Efficiency and Cost Savings

Compared to traditional disassembly and repair methods, industrial borescope allows for internal inspections without interrupting production or shutting down operations, greatly saving time and costs. Operators do not need to invest a significant amount of manpower and resources in dismantling and reassembling equipment; they can simply perform visual inspections using the borescope. This not only improves work efficiency but also reduces maintenance and repair costs.

12.Support for Education and Training

Industrial borescope plays a crucial role not only in practical work but also as an educational and training tool. By transmitting the borescope's images to a large screen in a training room or classroom, students and trainees can watch and learn techniques for identifying internal structures and defects. This helps enhance their professional knowledge and skills, fostering the development of more professionals in the industrial field.

Industrial borescope not only provides insights into the inner workings of industries, revealing hidden defects, but also enables rapid problem localization and resolution, making it an indispensable tool in the field of industrial inspections. With its versatile functionality and wide range of applications, industrial borescope is empowering various industries to achieve higher levels of safety and quality control.

Digging Deep: How to Choose the Right Industrial Borescope?

Quality, Illumination, Materials, and Service: Exploring the Determinants of Industrial Borescope Pr

Automotive Borescopes: Efficient Visual Inspection Tools for Automotive Maintenance and Repair

Industrial Borescope: A Versatile Inspection Tool for Enhancing Safety and Efficiency

Industrial borescope Technology: An Effective Means to Enhance Aircraft Engine Safety

Perspective on industrial quality: Non-destructive testing technology of industrial Borescope

Using industrial video borescope technology to explore the unseen world inside industrial areas.

Using video industrial borescope inspection technology breaks the detection limitations in existing