In modern aviation industry, safety and reliability of aircraft engines and their components are crucial. To ensure their proper functioning and maintenance, industrial borescope inspection has become a necessary technological means.

Borescope inspection technology is a method of using high-precision optical instruments and cameras to inspect the inside of machinery. With this technology, engineers and technicians can observe the inside of machines without disassembling components to detect and eliminate possible problems.

The application of borescope inspection technology in the aviation industry is very extensive, especially in the inspection of aircraft engines and their components. The engine is the core component of an aircraft, and its quality and safety are directly related to the safety and normal operation of the aircraft. Due to the harsh working environment of aircraft engines, they are often subject to various factors such as high temperature, high pressure, and high speed, so regular inspection and maintenance of the engine and its components are necessary.

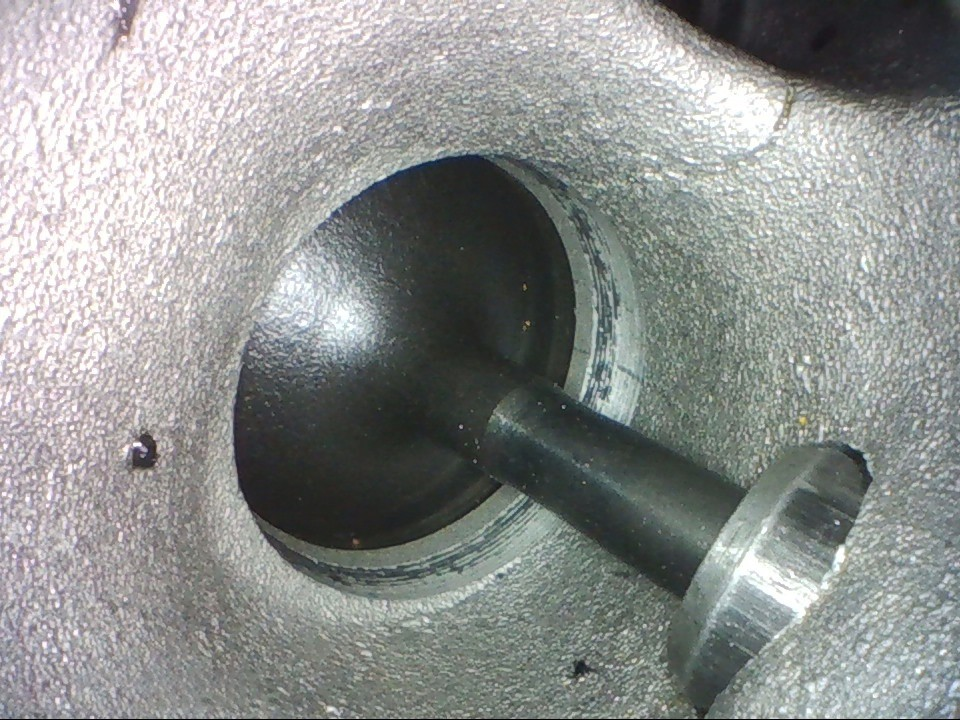

Industrial borescope inspection technology can transmit high-resolution images to a screen through a probe, allowing technicians to clearly observe the inside of the engine, including the rotor, blades, intake duct, combustion chamber, and other areas, in order to detect and address any potential defects, damage, or corrosion. These problems may be small cracks, holes, or corrosion, but over time they can expand and cause engine failure, so they must be identified and resolved in a timely manner.

In addition to engine inspections, industrial borescope inspection technology can also be applied to other aircraft components such as the fuselage, wings, landing gear, and more. Through these inspections, various issues such as defects, cracks, corrosion, fatigue, and more can be detected and addressed in a timely manner, ensuring safe and normal aircraft operation.

Industrial borescope inspection technology has many advantages in inspecting aircraft engines and their components.

1.Non-destructive testing: Industrial endoscope inspection technology is a non-destructive testing method, which does not cause secondary damage to the inspected parts, thereby reducing the maintenance cost and time of the equipment, and also extending the service life of the equipment.

2.High detection accuracy: Industrial endoscope inspection technology can provide high-precision inspection results and can detect tiny defects and damages such as hairline cracks and small holes, so that they can be discovered and repaired in a timely manner before the problem expands, avoiding the risk of equipment failure and accidents.

3.Easy operation: Industrial endoscope inspection technology requires a small amount of manpower and equipment investment, and is easy to operate. It does not require large-scale disassembly and assembly of the inspected parts and can be completed in a short time.

4.Safe and reliable: Industrial endoscope inspection technology can observe the internal situation of the equipment from a distance, avoiding the risk of technicians operating the equipment in a dangerous environment. It also reduces the safety hazards that may exist during equipment maintenance and repair processes.

5.Data visualization: Industrial endoscope inspection technology can generate high-quality image and video data. Through this data, inspection results can be visualized, which is convenient for engineers and technicians to analyze and judge, thereby better formulating maintenance plans.

In addition to the inspection of aircraft engines and their components, industrial endoscope technology can also be applied in other fields such as petroleum, chemical, energy, etc. In these fields, industrial endoscope inspection technology can also offer the same advantages and application values.

Digging Deep: How to Choose the Right Industrial Borescope?

Quality, Illumination, Materials, and Service: Exploring the Determinants of Industrial Borescope Pr

Automotive Borescopes: Efficient Visual Inspection Tools for Automotive Maintenance and Repair

Industrial Borescope: A Versatile Inspection Tool for Enhancing Safety and Efficiency

Industrial borescope Technology: An Effective Means to Enhance Aircraft Engine Safety

Perspective on industrial quality: Non-destructive testing technology of industrial Borescope

Using industrial video borescope technology to explore the unseen world inside industrial areas.

Using video industrial borescope inspection technology breaks the detection limitations in existing